5 Benefits of Lean Six Sigma Green Belt Certification

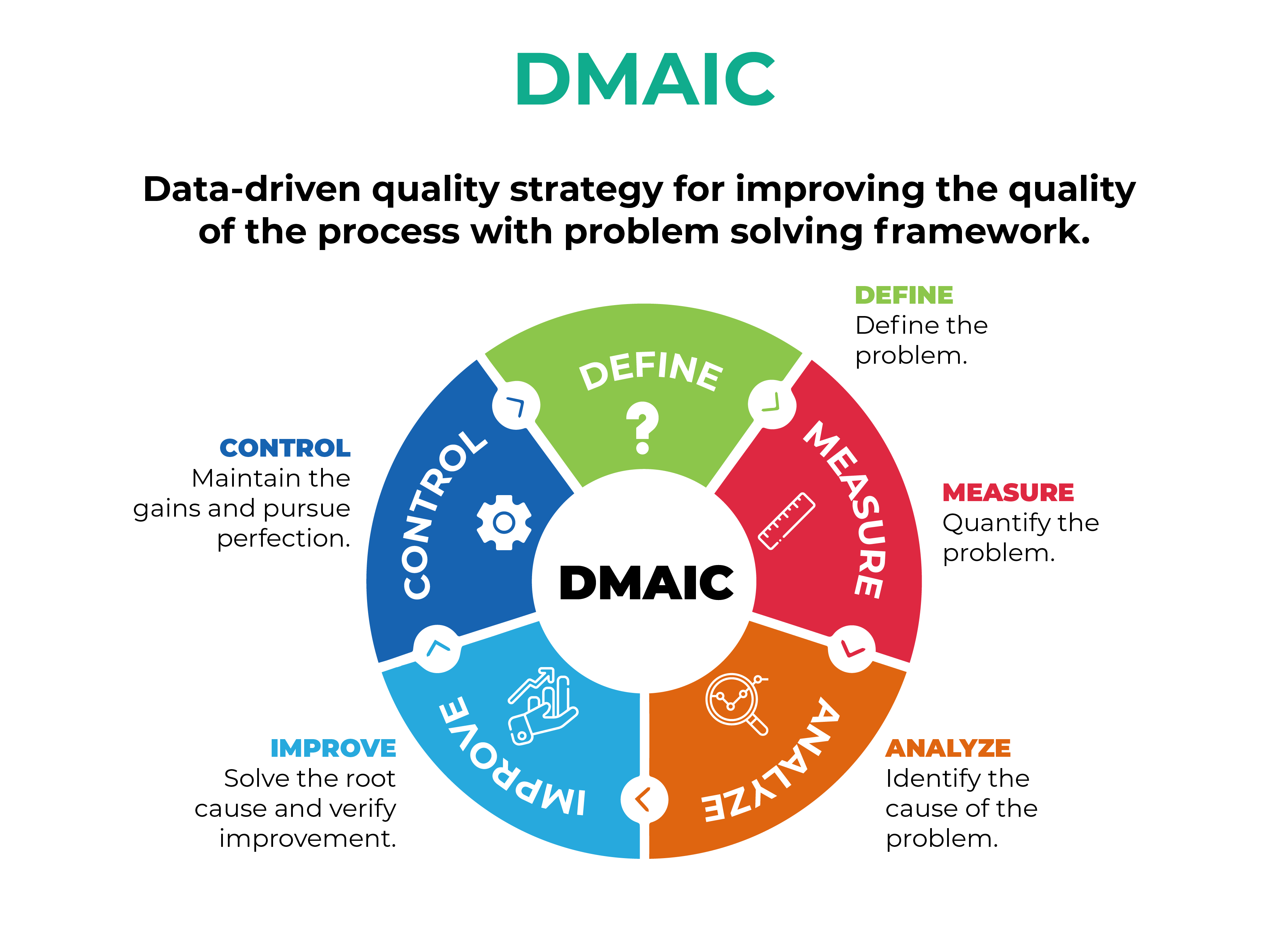

Statistical data analysis. Design of experiments. Hypothesis testing. Lean Six Sigma focuses on reductions in waste using processes such as: Kaizen. Workplace organization. Visual controls. In most cases, organizations today incorporate both methodologies into their Six Sigma quality management practices.

7 Lean Six Sigma Methodology Can Speed Up Your Business Growth

Lean Six Sigma certification is a credential that shows someone's skills and proficiency in the Lean Six Sigma methodology. Like Six Sigma, the Lean Six Sigma framework improves an organization's processes, decision-making, and operational efficiency while reducing waste and cost. The overall goal of implementing Lean Six Sigma processes is.

Lean Six Sigma uma estratégia para vencer a competitividadeIPOG

Lean Six Sigma 4.0 represents the seamless integration of traditional Lean Six Sigma principles with cutting-edge technologies, fostering a new era of efficiency, innovation, and adaptability. Lean Six Sigma 4.0 harnesses Industry 4.0 technologies like data analytics, artificial intelligence, IoT, and automation.

What Is Lean Six Sigma? How to Apply It in Your Organization

Lean Six Sigma employs statistical analyses for informed decision-making. This diminishes subjectivity in business decisions, allowing organizations to identify and address the root causes of problems more effectively. Cost Reduction. Lean Six Sigma significantly reduces operational costs by eliminating waste, rework, and defects.

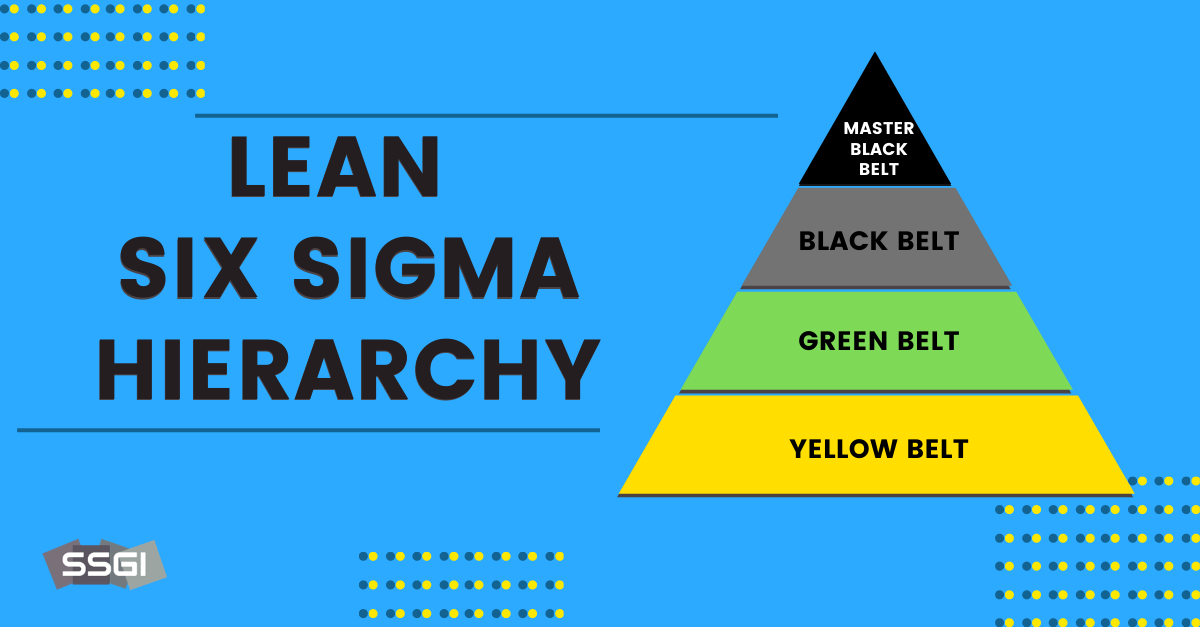

Lean Six Sigma The Definitive Guide (2024) SSGI

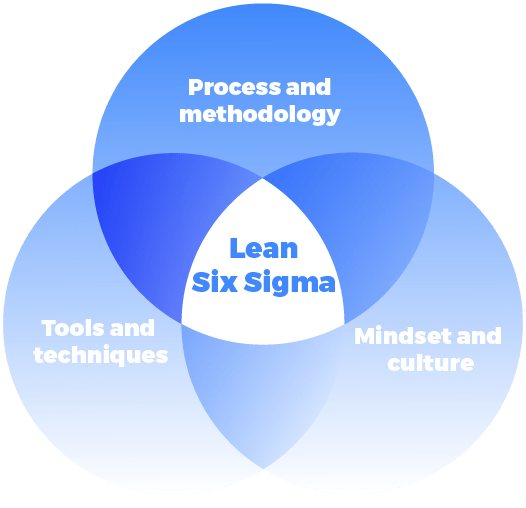

Lean Six Sigma has emerged as a powerful methodology to enhance efficiency, reduce waste, and drive continuous improvement within organizations. One of the key elements that make Lean Six Sigma so effective is the wide array of tools and techniques it offers to identify problems, analyze data, and implement solutions. In this blog post, we'll.

Henry Ford and the Roots of Lean Manufacturing Six Sigma Daily

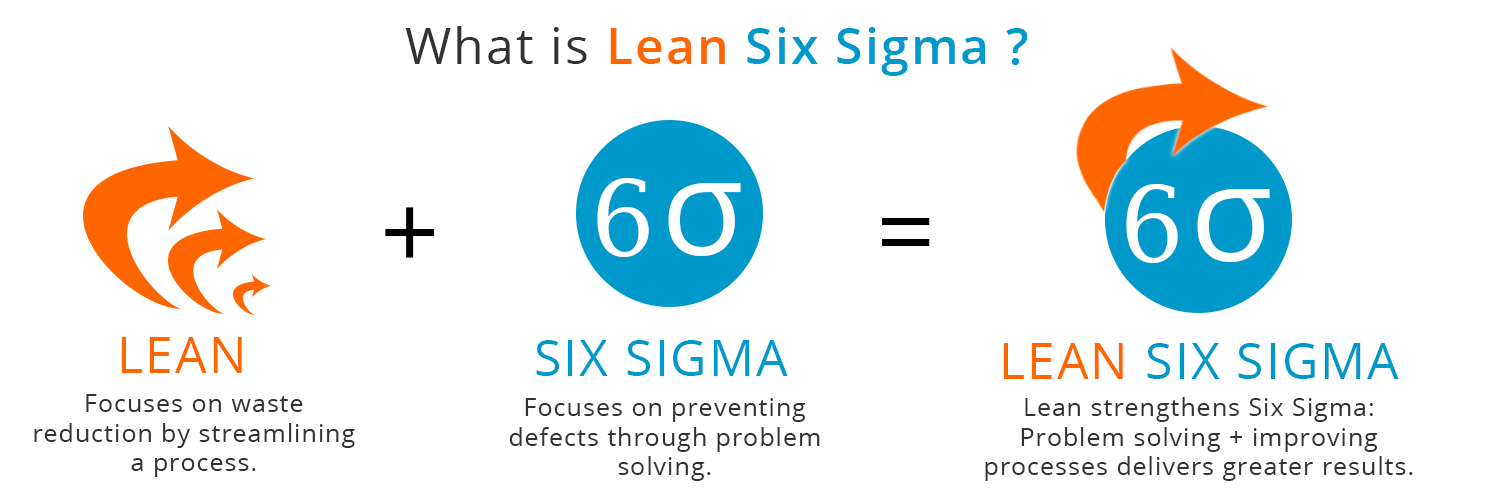

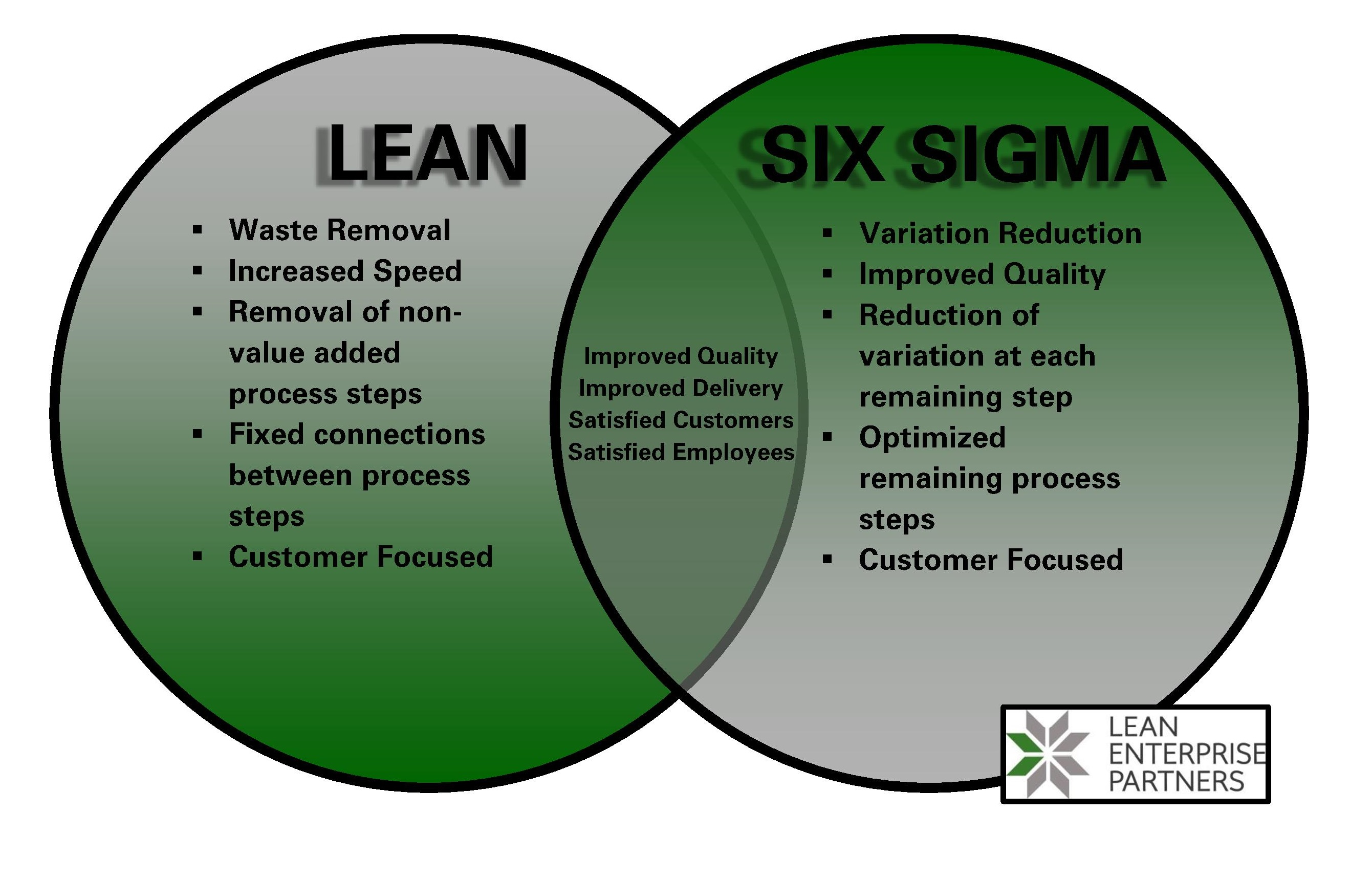

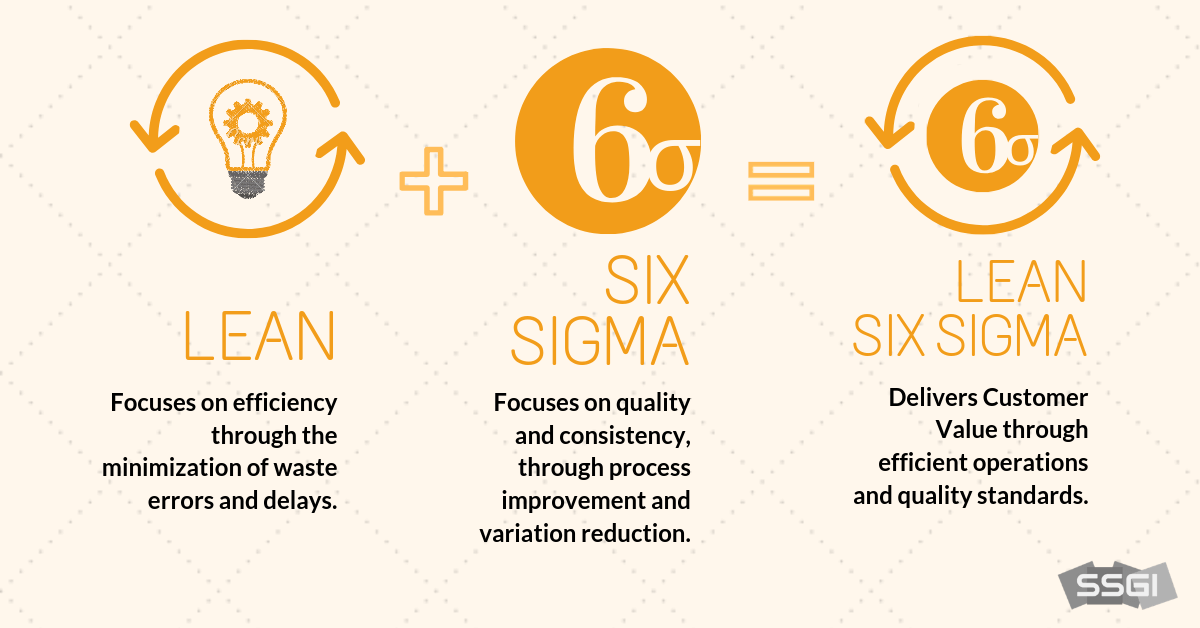

Lean Six Sigma is a synergized managerial concept of Lean and Six Sigma. [5] Lean traditionally focuses on eliminating the eight kinds of waste ("muda"), and Six Sigma focuses on improving process output quality by identifying and removing the causes of defects (errors) and minimizing variability in (manufacturing and business) processes.

Lean 6 Sigma Finbrain ITC

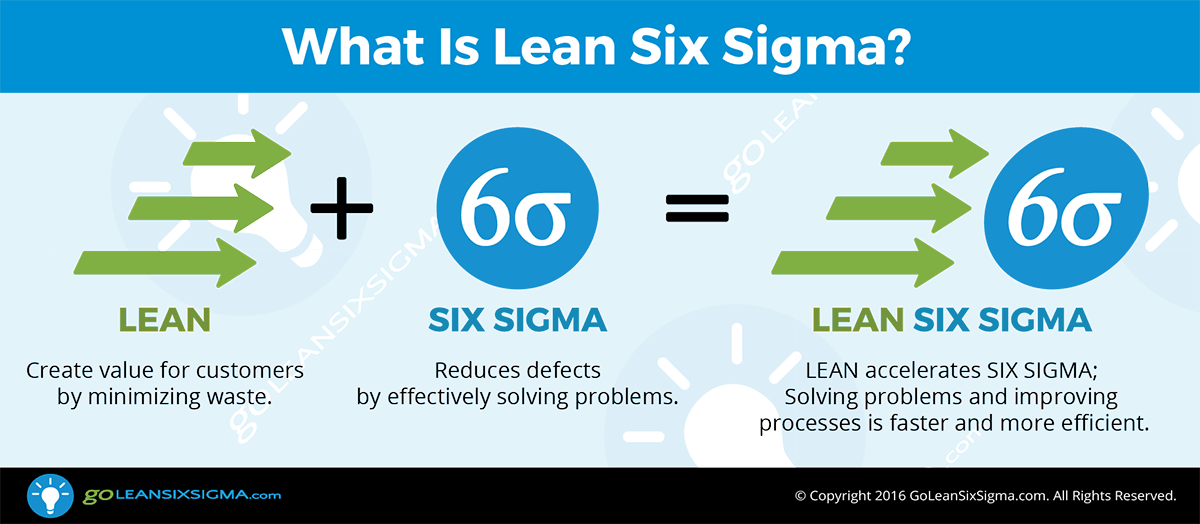

Lean Six Sigma brings together principles from lean manufacturing and Six Sigma. Lean manufacturing is a philosophy that emphasizes the elimination of waste and the improvement of production flow through collaborative team effort. Six Sigma is a data-driven methodology that uses statistical analysis and problem-solving tools to identify and eliminate defects as well as process variations.

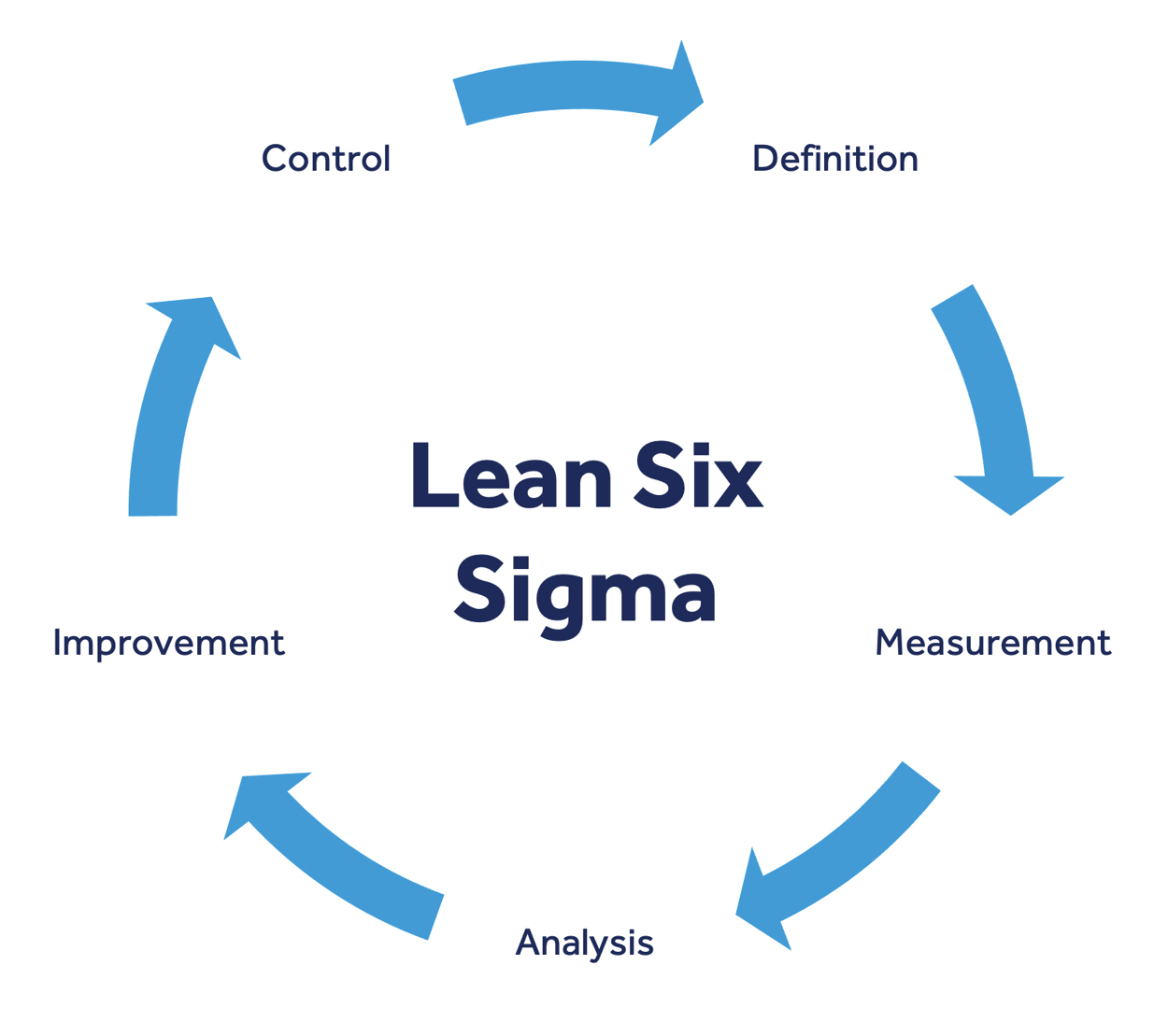

What are the 5 phases of Lean Six Sigma? iCert Global

Lean Six Sigma is a powerful operational improvement methodology that synergizes the efficiency-focused Lean principles with the quality-centric Six Sigma approach. Originating from the best practices of Japanese manufacturing, particularly Toyota's Production System, Lean emphasizes creating more value for customers using fewer resources..

How To Think About Lean vs Six Sigma YouTube

Per the definition provided by the American Society for Quality (ASQ), " Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection.". Lean acts as the detective, spotting any unnecessary bumps in your project flow. Six Sigma then jumps in as the fixer, using data and clever.

What is Lean Six Sigma?

To learn more about Purdue University's online Lean Six Sigma Training and Certification program and download a brochure, fill out this form. You can also email us at [email protected] or call us at (888) 390-0499 to speak to one of our program advisors. Purdue University has engaged AllCampus to help support your educational journey.

Lean Enterprise Partners Blog

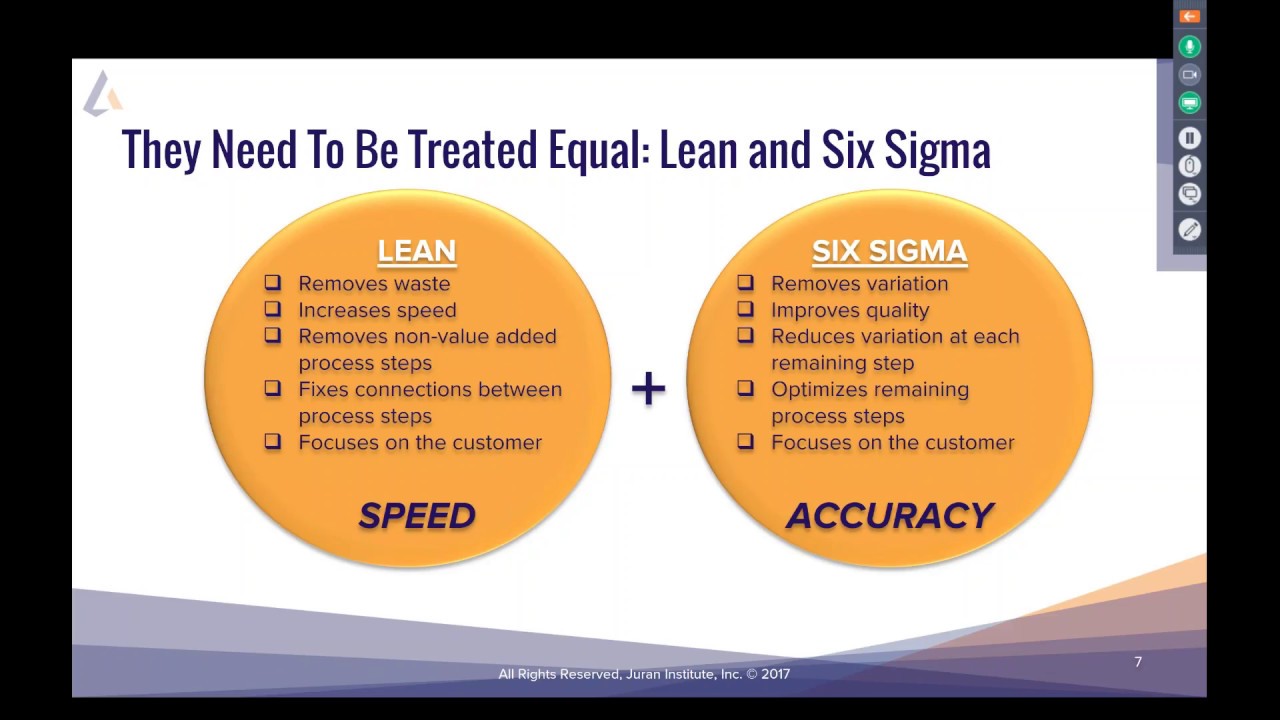

Lean principles focus on eliminating waste and improving process flow, while Six Sigma emphasizes reducing defects and variations. When combined using Lean Six Sigma, these principles create a holistic approach that optimizes efficiency and quality, resulting in streamlined, high-performing processes. 1.

Lean Six Sigma Training and Certification with International Accreditation

Lean Six Sigma is a managerial approach that combines Six Sigma methods and tools and the lean manufacturing/lean enterprise philosophy, striving to eliminate waste of physical resources, time.

What’s the Difference Between Lean Six Sigma and Six Sigma? SSGI

Lean Six Sigma (LSS) is a project management methodology. It equips organizations across the spectrum—from Fortune 500 giants to government bodies, nonprofits, and small- to medium-sized enterprises—with the tools to reduce costs, boost productivity, and deliver unparalleled customer value. Every organization in every industry has processes.

:max_bytes(150000):strip_icc()/Lean_Six_Sigma_Structure_Pyramid-671e13ecc9e84e6e922d961234f57124.png)

Lean Six Sigma Definition, Principles, and Benefits

The primary difference between Lean and Six Sigma is that Lean is less focused entirely on manufacturing, but often shapes every facet of a business. Lean Six Sigma combines these two approaches, which creates a powerful toolkit for addressing waste reduction. As companies seek to understand where they may have wasteful practices in place, the.

What is Lean Six Sigma TristiankruwBarton

The primary aim of the Lean method is to reduce waste. The goal of Six Sigma is to reduce variation for optimal quality control. The discipline known as Lean Six Sigma (LSS) blends these two approaches. Refinements to the production process are essential to managing and reducing the 8 wastes analyzed by the Lean method.

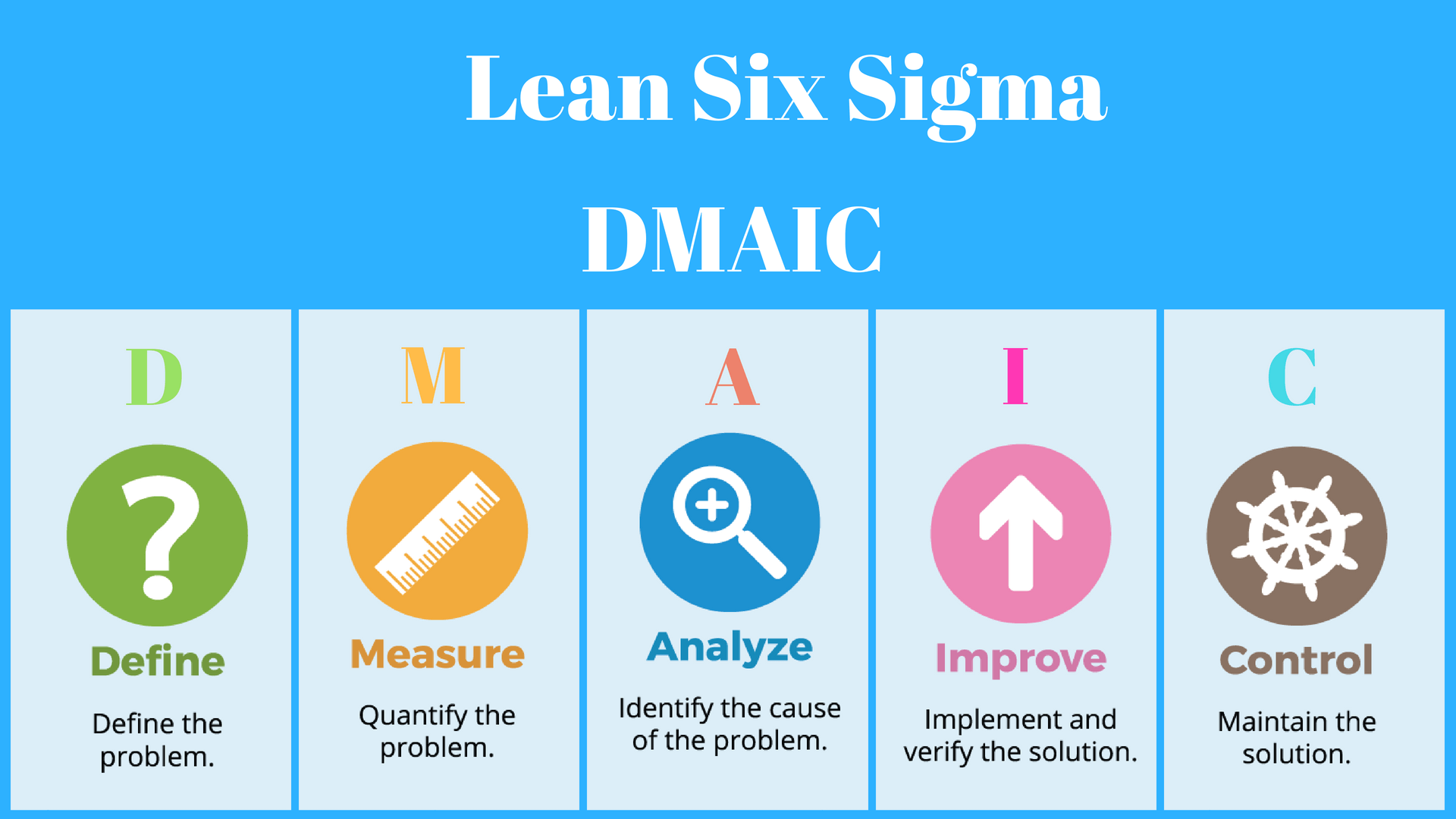

How is Lean Six Sigma DMAIC Process Defined?

Lean Six Sigma is a process improvement methodology designed to eliminate problems, remove waste and inefficiency, and improve working conditions to provide a better response to customers' needs. It combines the tools, methods and principles of Lean and Six Sigma into one popular and powerful methodology for improving your organization's.

- Hoeveel Belasting Betaal Je Na Je Aow Leeftijd

- Wanneer Rijden Er Weer Treinen Tussen Leiden En Den Haag

- Easeus Partition Master License Code 2023

- Race To The Finish Spel

- Hoe Ontstop Je Een Gootsteen

- Hoeveel Verdient Rutte Per Jaar

- The Hunger Games Book 1

- It Must Be Love Lyrics Roxette

- Windows Media Player 11 Downloaden Gratis Nederlands

- Hoe Krijg Je Een Hoger Testosteron