How Plate Heat Exchangers Work MEP Academy

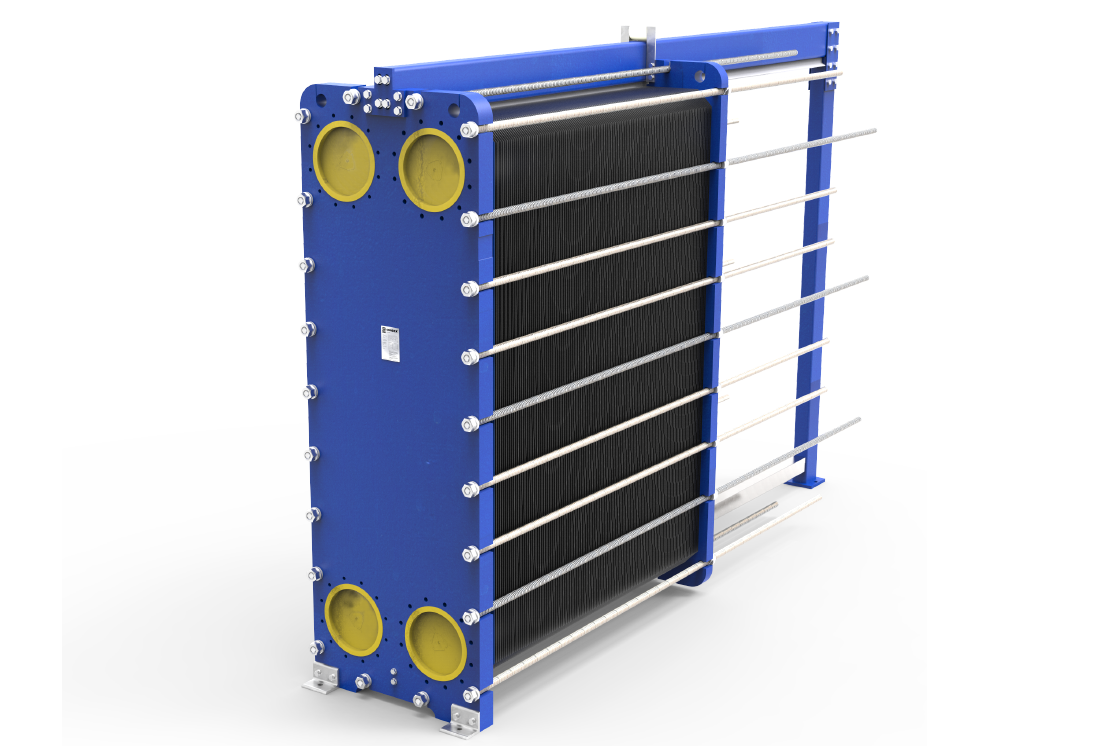

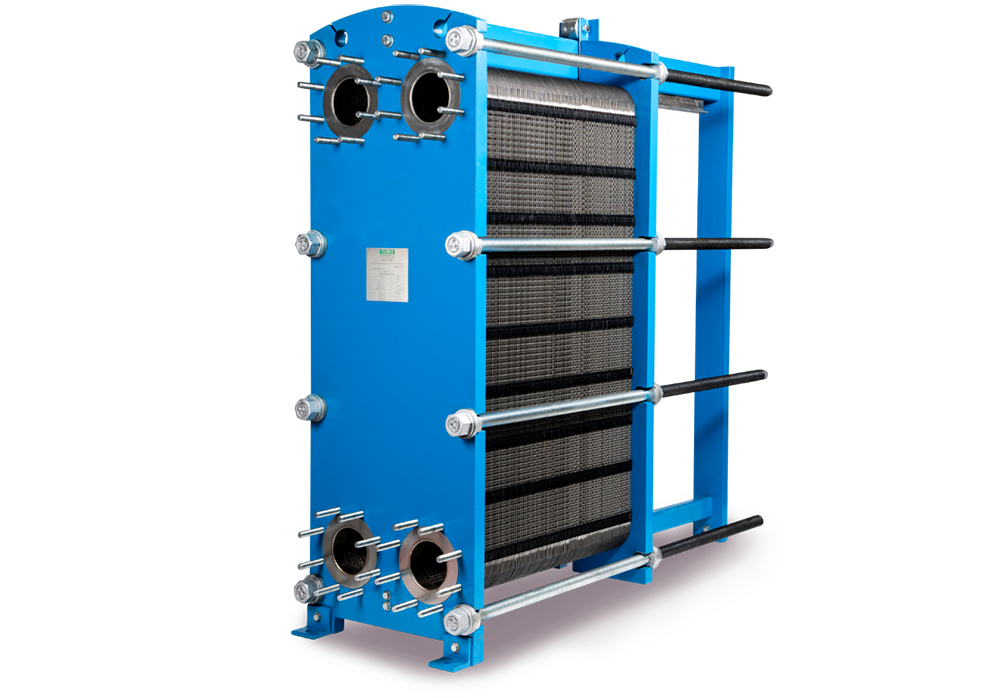

Efficient heat transfer. Gasketed plate-and-frame heat exchangers (GPHEs) provide efficient heat transfer in compact equipment with a small footprint - much smaller and more efficient than shell-and-tube heat exchangers. Our wide range of products is used in duties for heating, cooling, heat recovery, evaporation, and condensation in.

Advantages and Disadvantages of a Plate Heat Exchanger Stoll

The plate and frame heat exchanger uses to exchange heat between liquid and liquid at medium to low pressure. You can safely use a plate and frame heat exchanger without a gasket at high temperature and pressure. This type of heat exchanger has high flexibility as plates can be compressed or added in various situations.

API Energy Gasketed Plate & Frame heat exchangers Alyamitech

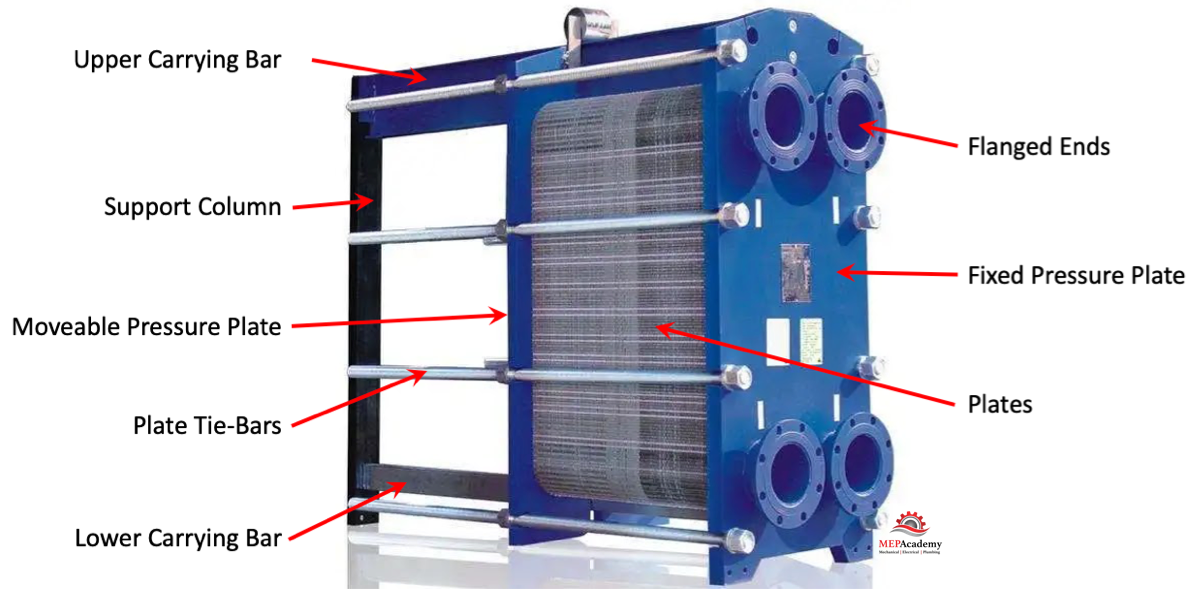

Plates for a gasketed plate heat exchanger are with elastomeric gaskets. These seal the channels and direct the mediums into alternate channels. The plate pack is between the frame plate and a pressure plate. It's then compressed with bolts between the plates. The upper carrying bar supports the channel and pressure plate.

Plate Heat Exchanger (PHE) Explained saVRee saVRee

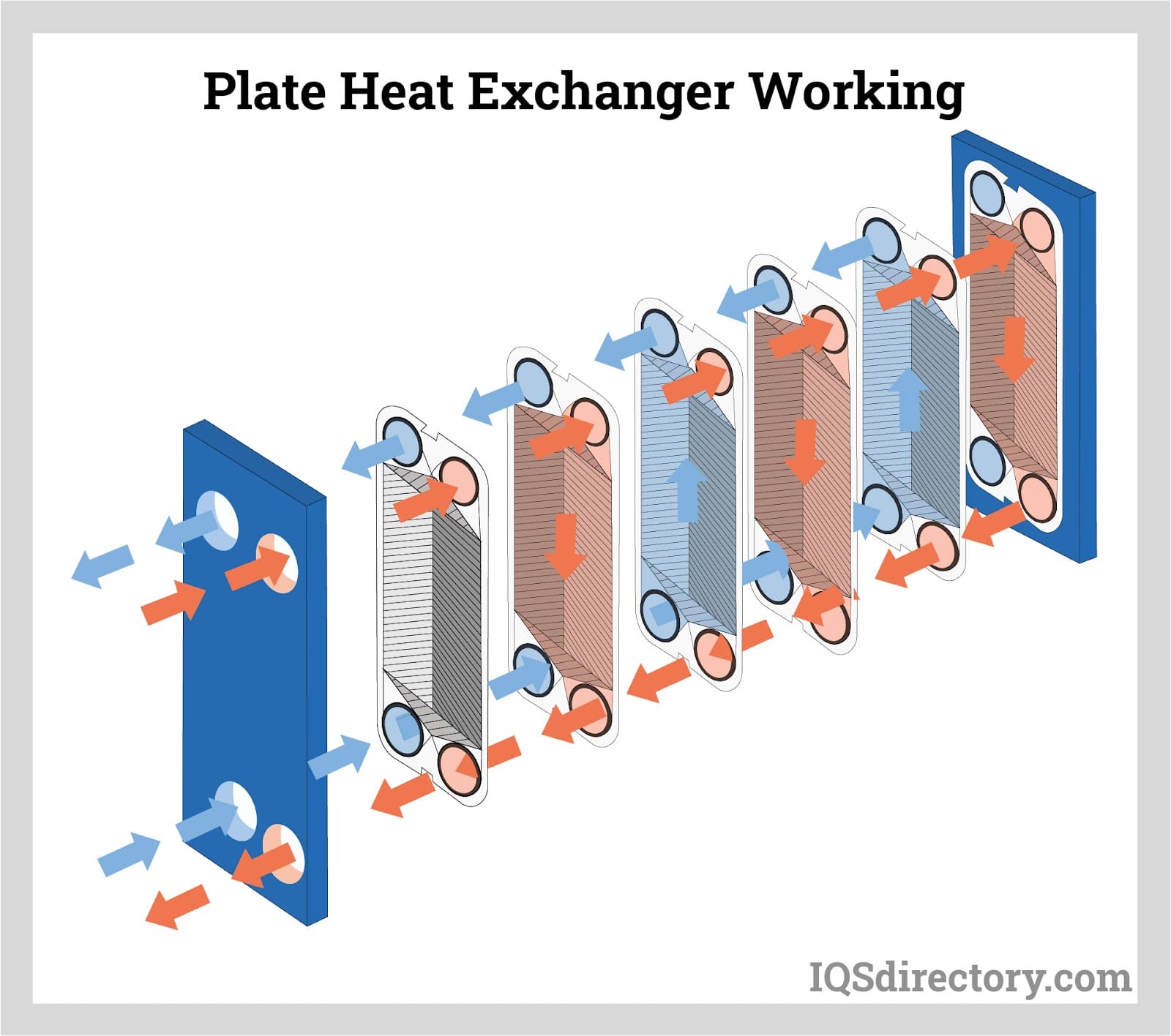

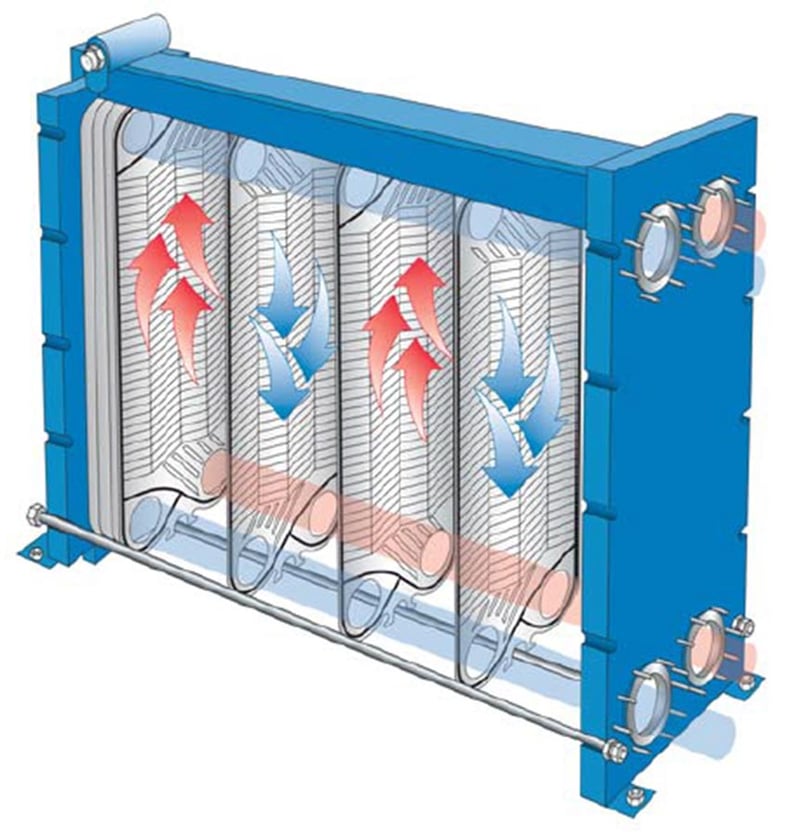

If we pass the cooler fluid into the heat exchanger, we can let it enter via the top left inlet. It will then flow into plates 2, 4 and 6. It will then leave a higher temperature via the bottom left outlet. We then have the hot fluid entering via the lower right inlet, it flows through channels 1, 3, 5 and 7.

Plate and Frame Heat Exchanger Cleaning Methods The Merrick Group

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the media into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates. The channel plates and the pressure plate are suspended.

Plate and Frame Heat Exchanger What, How, Types, Working, Sizing, Cleaning, Applications

The Alfa Laval HEXpert selector tool makes it quicker than ever to find your ideal heat exchanger. Just answer a few short questions and get a customized recommendation to meet your unique needs. The tool currently covers products for design pressures up to 100 bar and design temperatures up to 450° C. Try the HEXpert selector tool.

API Energy SemiWelded Plate and Frame Heat Exchanger(SWPHE) API Energy

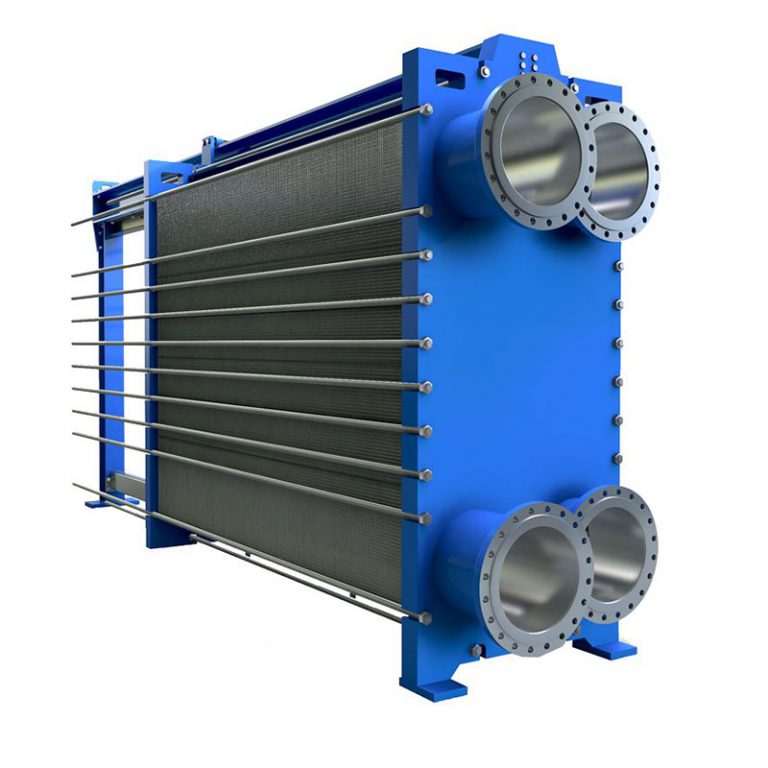

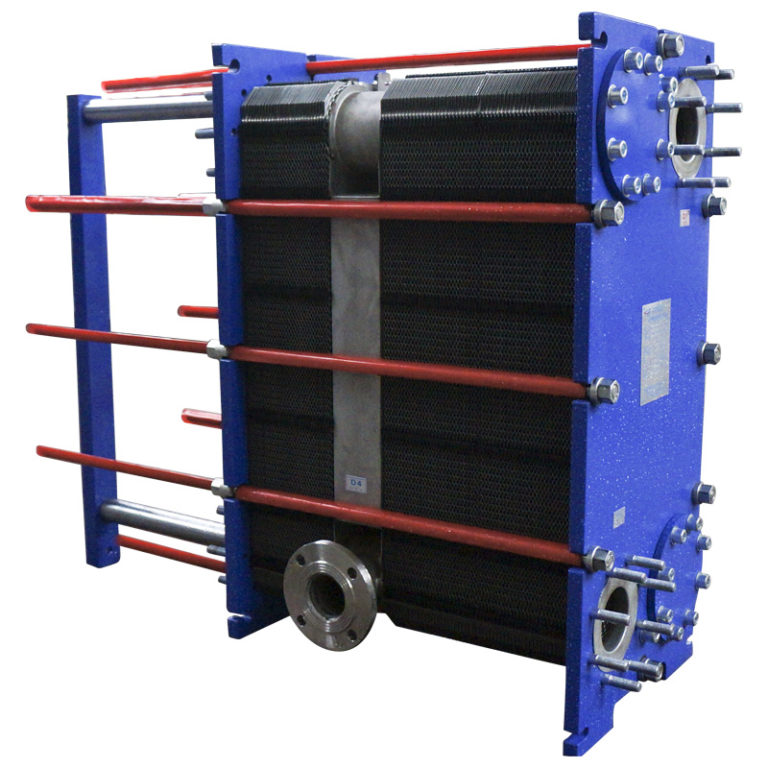

The plate and frame heat exchanger is a device which is uses in a sequence of metal plates where the heat is freely move one fluid to another fluid. The plates of the plate and frame heat exchanger placed over each other thus it could create a sequence channel so the pressure fluid can move inside of it.

Plate Heat Exchangers Components, Types, Applications and Advantages

In the Plate And Frame heat exchanger design, pressed corrugated metal plates are assembled in a pack and bolted in a frame. Between each pair of plates there is a rubber gasket, which prevents the fluids from being mixed and from leaking out of the plate pack to the surroundings. The plates hang from a top carrying bar and are located by the.

Plate Heat Exchanger (PHE) Explained saVRee saVRee

Plate and frame heat exchangers are made of corrugated plates on a frame. This design creates high turbulence and high wall shear stress, both of which lead to a high heat transfer coefficient and a high fouling resistance. F luids travel within the heat exchanger. The two streams flow counter currently.

Plate Heat Exchangers WCRHX

The Armstrong PFX plate and frame heat exchangers consist of a number of specially corrugated metal plates assembled in a frame and bolted between two pressure plates (one fixed and one adjustable.) Armstrong plate designs are optimized for best water-to-water heat transfer providing enhanced performance especially in HVAC applications. Materials.

Plate Heat Exchanger Cleaning Heat exchanger, Heat, Mechanical engineering

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids.This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change.

All About Plate Heat Exchangers What You Need To Know

In this video we learn how a plate heat exchanger works, covering the basics and working principles of operation. We look at 3d models, animations and real w.

Which Heat Exchanger Is Best? The Three Main Types Explained...

We would like to show you a description here but the site won't allow us.

SRSINTLDIRECT

Quickly heat or cool beverages and condiments using these heat exchangers, which have a sanitary design certified by 3- A. Also known as plate and frame heat exchangers, they run your product through stacked, corrugated plates and send a liquid of a different temperature in the opposite direction. They're more efficient than shell and tube.

SRSINTLDIRECT

Plates are pressed in materials between 0.5 and 1.2 mm thick and plates are available with effective heat transfer area from 0.03 to 3.5 m 2. Up to 700 plates can be contained within the frame of the largest Paraflow exchanger, providing over 2400 m 2 of surface area. Flow ports and associated pipework are sized in proportion to the plate area.

Welded Plate and Frame Heat Exchanger

2-Pass GPHE. The animation above shows the working principle of an Alfa Laval liquid/liquid 2-pass gasketed plate-and- frame heat exchanger where the fluids run counter-currently through the heat exchanger. The turning plate in the middle of the plate pack directs the flow into the two passes. The hot liquid (illustrated in red) enters through.

- It S Okay Not To Be Okay Reviews

- Rose Aix Gall En Gall

- Gondwana Game Reserve South Africa

- The Tag Present In The Reparse Point Buffer Is Invalid

- Rise Of The Tomb Raider Boss Fight

- Jannes Liefde Is Meer

- Death In Paradise Season 12

- Lady With The Dragon Tattoo Book

- Sony Cybershot Dsc Rx 1000

- 5 Letter Words Ending In Ile